White Metal Bearings

Manufacturing of White Metal Bearings to customer’s drawings has been the core of our business for over a hundred years.

We offer a full bearing design, manufacturing, reverse engineering and repair service for white metal bearings.

We are approved suppliers across the range of multi-nationals to development start-ups in the engineering, defence, maritime, oil & gas and electricity supply industries. We can supply large thrust and journal bearings for power generating equipment to small high performance bearings for high-speed compressors.

Wide range of products

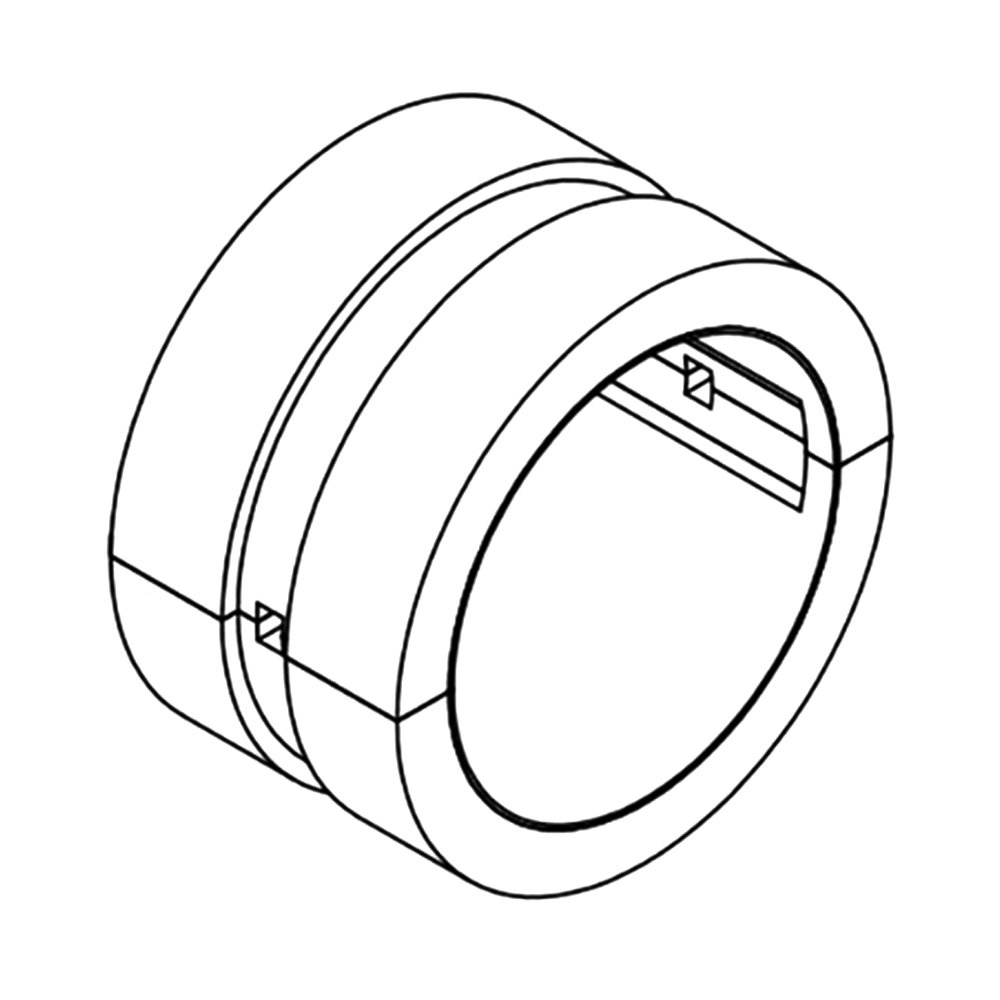

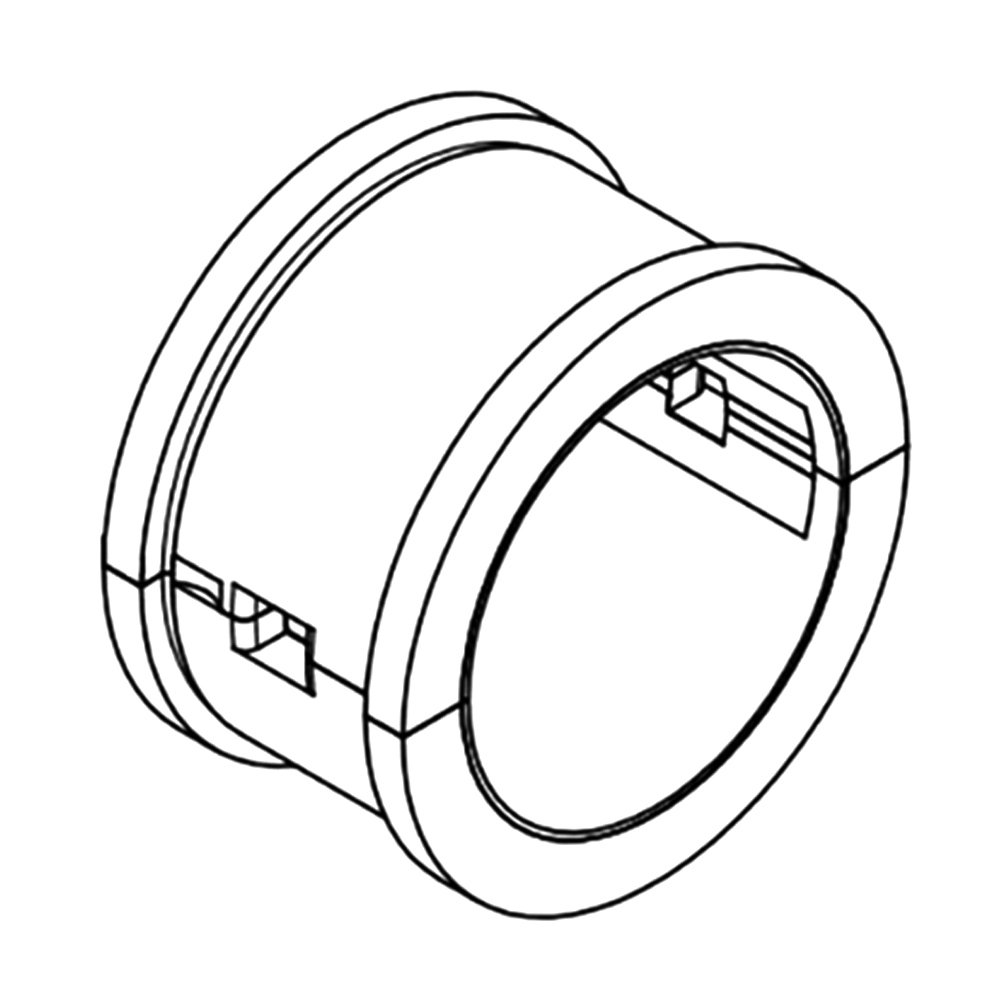

Coleherne manufacture journal bearings for OEMs, service companies and end users around the world. These bearings are manufactured according to the customer’s drawings and specifications. We can machine cylindrical, elliptical and multi-lobe profiles for our plain journal bearings.

Our range of fixed bore profiles includes:

Cylindrical

Elliptical (‘Lemon Bore’)

Offset Halves

Four Lobe

We also offer a full bearing design service where we take the application conditions (speed, load, oil etc), conduct a full bearing analysis with all the bearing performance calculations and produce manufacturing drawings.

Our skill and experience allow us to design and manufacture almost every combination of journal and/or thrust bearing configuration, bore profile, material, lubrication system and assembly type.

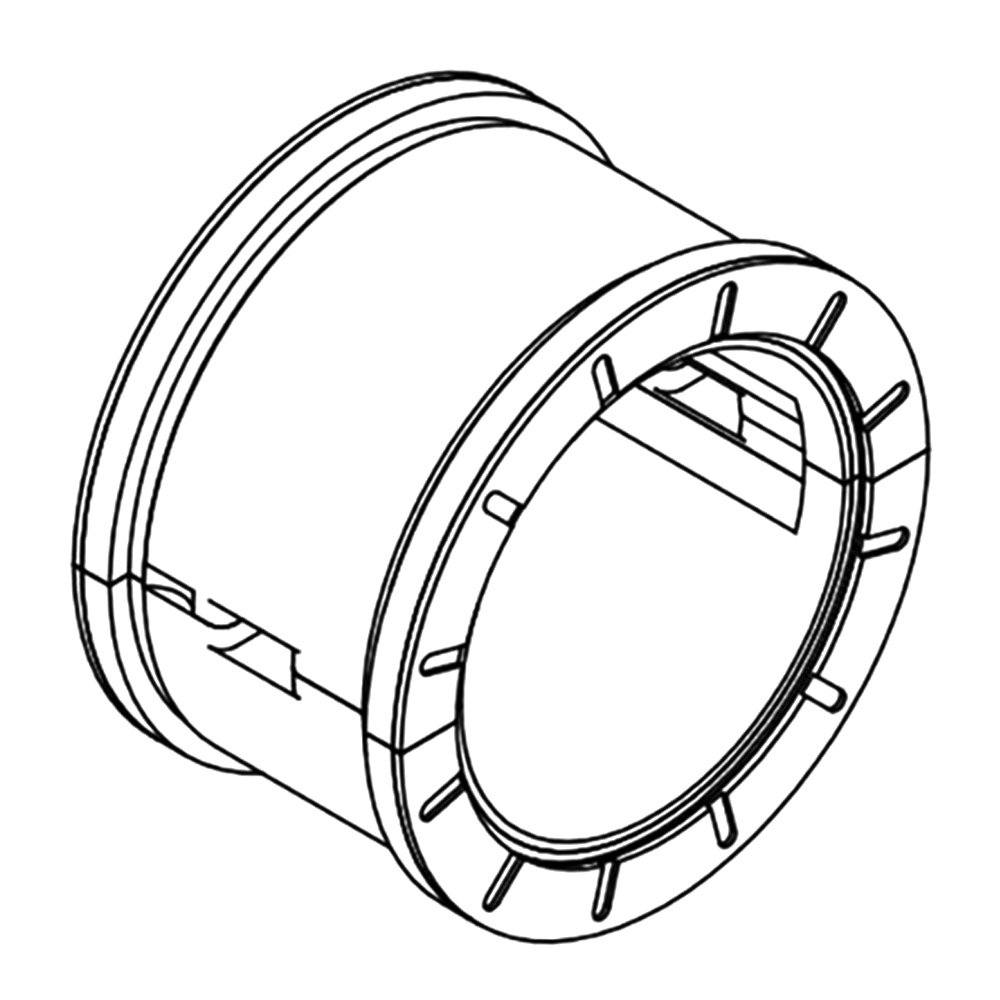

We supply tilting pad journal & tilting pad thrust bearings, combined thrust and journal bearings, planetary gearbox spindles, seals and baffles. Our range of journal and thrust bearings is continuously changing to cover larger and more sophisticated technical products demanded by advanced technology.

Our range of tilting pad journal and thrust bearing assemblies includes:

Fixed Profile Bores

Taper Land Thrust

Tilting Pad Journal

Tilting Pad Thrust

Pivot Systems – Offset, Ball & Socket, Equalising Link

Combined Journal and Thrust Assemblies

Direct (Forced) Lubrication

Indirect (Flooded) Lubrication

Oil Jacking Systems

Conventional or Compact Construction

Cooling Systems

Sealing Systems

We also offer several options for external performance measurement:

Temperature

Vibration

Load

Wide Range Of Materials

Our new bearings are typically manufactured using a normalised mild steel backing with a white metal lining to BS3332/A. We usually keep an extensive range of Bronze, Steel, Cast Iron and White Metal in stock in order to our meet customers delivery expectations.

White Metal Alloys

White metals (also known as Babbitt) are bearing alloys usually Tin-based but some legacy bearing designs may contain Lead. Tin-based alloys are Tin alloyed with Antimony and Copper with some proprietary alloys containing minor alloying elements such as Cadmium, Zinc or Silver. The common standards in use at Coleherne are BS3332, ISO 4381 and ASTM B23, the main alloys in use are shown in this table:

| Grade | Tin (Sn) | Antimony (Sb) | Copper (Cu) | Lead (Pb) |

|---|---|---|---|---|

| BS3332 Grade A | Remainder | 7.0 - 8.0% | 3.0 - 4.0% | 0.35% max |

| BS3332 Grade C | Remainder | 8.5 - 10% | 3.5 - 5.0% | 0.35% max |

| BS3332 Grade F | 5.0 - 7.0% | 9.0 - 11.0% | 0.7% Max | Remainder |

| ISO 4381 SnSB8Cu4 | Remainder | 7.0 - 8.0% | 3.0 - 4.0% | 0.35% max |

| ASTM B23 Grade 2 | Remainder | 7.0 - 8.0% | 3.0 - 4.0% | 0.35% max |

Other proprietary alloys, for instance, Tegostar 738®, are available on request.

Full material traceability is compliance with ISO-9001 with material certification in compliance with EN10204 Type 3.1.

White Metal Lining

We use the Centrifugal Casting process that is backed-up by the Static Lining process.

An outline of our bearing manufacturing process:

Full inspection of backing materials

Splitting and rough machining and heat treatment as required

Machining of the bonding layer on the backing material

Grit blast and apply special coatings to the bearing backing

Immersion tinning to create the bonding layer

Depending on the form of the backing, either centrifugal or static lining

Proof machining

Ultrasonic (on request) and dye penetrant to agreed standards

Removal of excess white metal from joint faces

Final machining of the white metal to standard or agreed dimensions

Ultrasonic (on request) and dye penetrant testing to agreed standards

Final dimensional inspection

Protection, packaging, certification and delivery.

Testing and Inspection

Our Level 2 NDT operators use sophisticated ultrasonic testing equipment and dye penetrant testing chemicals to check for Bonding of the White Metal to the backing material. This testing and reporting is done to the customer’s requirements or International Standards as required.

We use a bespoke oil flushing system to remove swarf and other debris from complex internal lubrication systems prior to inspection with a video borescope.

A lightweight industrial videoscope is used by our highly experienced inspection team to produce high-resolution video of the internal oil galleries to ensure they are free from burrs and other obstructions.

Coleherne uses a top-of-the range Zeiss Coordinate measuring machine for the final dimensional inspection of all our bearings before despatch. These dimensional reports are available on request.