Laser Cutting

We are proud of our reputation for supplying the finest quality laser cut products in the Greater Manchester area and across the UK.

We manufacture bespoke laser cut profiles for the OEM and the repair markets in the oil & gas, electricity supply, industrial pump, architectural, food & pharmaceutical packaging sectors.

Laser cut parts for prototypes, rotors, generators, architectural, machinery.

Post-processed laser cut parts – folded, bent, fabricated, painted, assembled.

Reverse engineering of irreplaceable or obsolete parts.

Laser cutting facilitates

Accuracy and repeatability of the cut elements, no other method can match the laser cutting process.

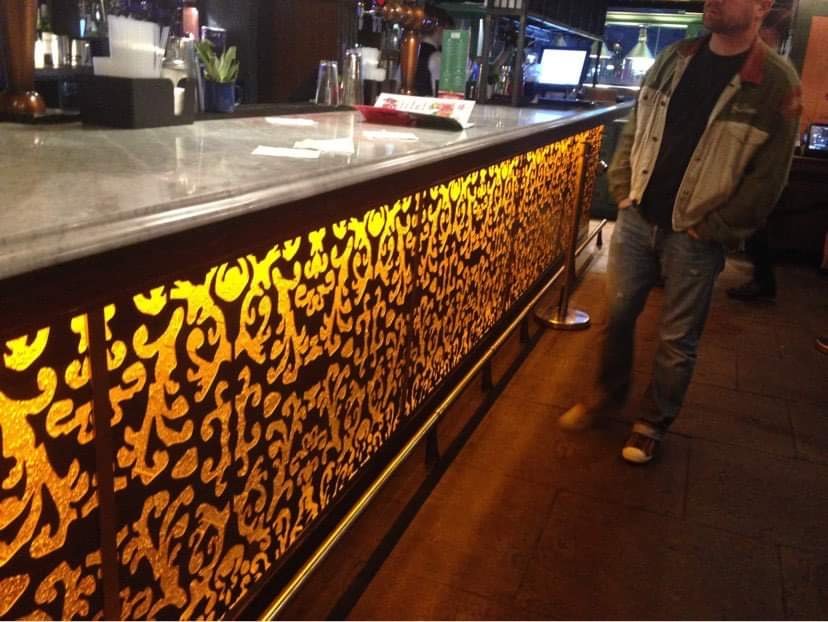

Cutting a wide range of intricate bespoke designs.

Working with a range of materials Mild and Stainless Steel, Aluminium, Copper, Brass, Titanium on request and more.

Our markets include: power generation, nuclear, hydro, public arts, architecture, food & pharma processing machinery, packaging equipment, shopfitting, fabricators, landscapers & designers.

Our 2 laser cells operate a shift system that runs 24 hours a day, 7 days a week

Precision components

Laser cut architectural facades

Production line machinery components

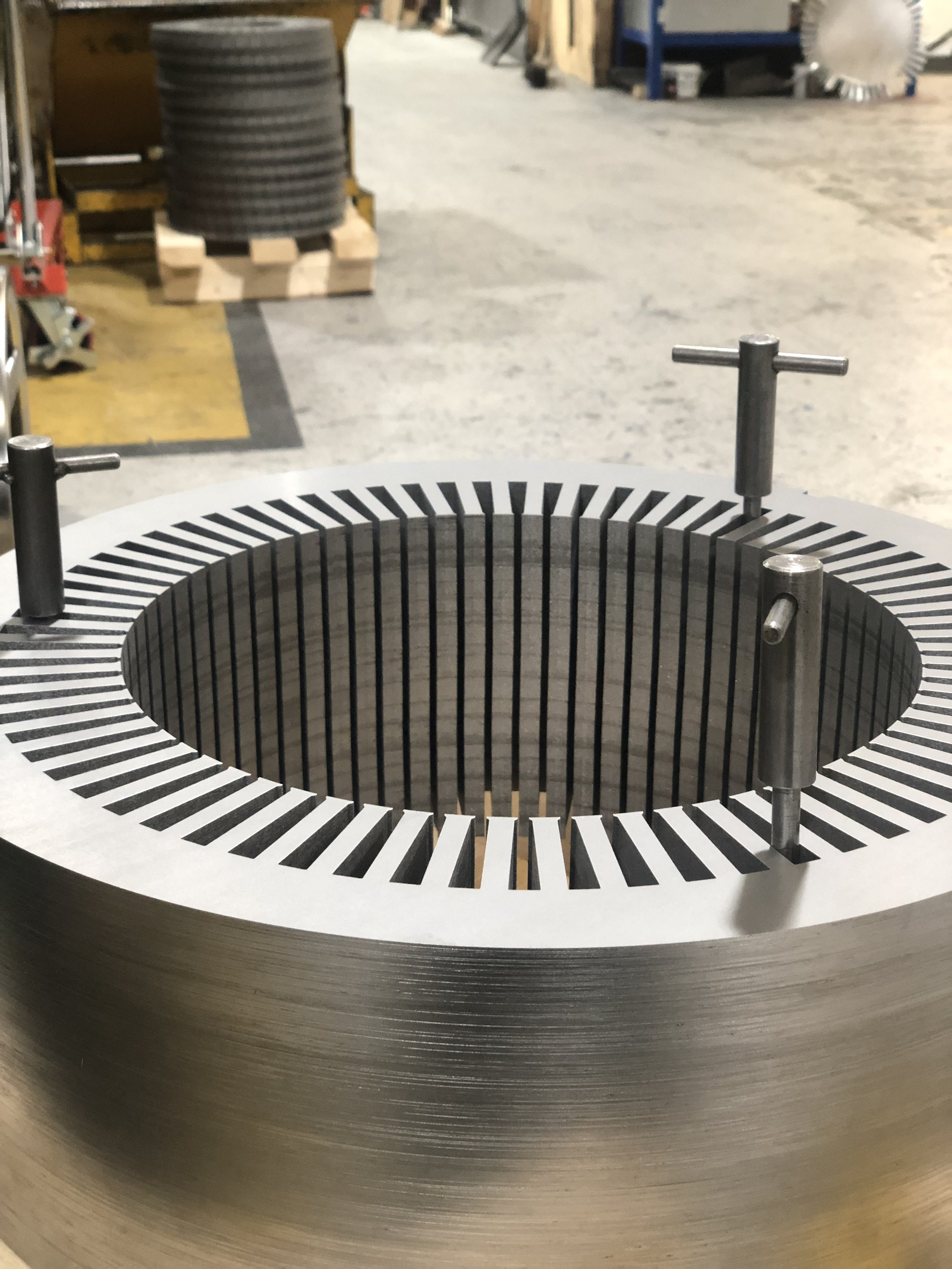

Laser cut electrical steel laminations

Our Capability

CAD & CNC laser cutting gives fast turnaround and consistent precision.

We cut large sheets of metal into intricate patterns to an accuracy of 0.1mm

Our fibre laser technology enables us to cut thicker plate and at faster speed.

Our expertise in laser cutting leads to bolder applications of this modern technology.

Our 2 laser cells operate a shift system that runs 24 hours a day, 7 days a week.

We hold a wide range of Mild and Stainless Steel, Aluminium, Copper, Brass, Titanium (on request), and more in stock.

Whether prototypes, components for industry or a bespoke sculpture, we will deliver any brief.

Cut depth capability in various materials

Materials

Mild Steel CR4, S275, S355 Grades

A versatile material used in industry for fabrications & architectural applications.

We can laser cut and fabricate sheet metal for any project, large or small.

Stainless Steel 304, 316 Grades

Stainless Steel is used in any industry where hygiene, clean finish and corrosion resistance are paramount.

The slightly rounded edges left from a cut do not require secondary finishing.

This durable metal is also ideal for street furniture or decorative cladding and a host of architectural products.

Shim Material

We cut specialist Electrical Steels specific for use in the lamination of transformers, electric motors, generators and pumps throughout the world.

Highly specialist, high quality, accurate work for OEM or repair projects.

Duplex, Super Duplex etc.

Electrical Steels to EN10106.

Aluminium / Alloy 1,5 & 6 Series

Aluminium is part of everyday life used in rigid and lightweight applications.

Used extensively in aerospace, automotive and military applications.

Our improved laser technology overcomes thermal and reflective properties.

We cut a range of Aluminium and its associated alloys up to 15mm in thickness.

Copper & Brass Various Grades

Applications include engineering and electrical due to its corrosion resistance and thermal & electrically conductive properties.

Newly developed anti-microbial Copper is used within the healthcare sector.

Copper and Brass are frequently used for decorative or sculptural purposes due to the inherent beauty of the metals.

Our improved laser technology overcomes thermal and reflective properties.

We cut a range of Copper and Brass alloys up to 10mm in thickness.

Titanium

Synonymous with the aircraft industry Titanium is corrosion resistant, fatigue resistant, lightweight and strong.

Our customers include architectural, engineers and designers.

When precision is paramount, our CNC cutting ensures the perfect result.

Production Process

We offer design, development, CAD-CAM and Machine Simulation.

We can work with your supplied files or create a product from a sample.

Highly qualified sales engineering team.

Reverse Engineering of Obsolete parts (3D Scanning).

Concepts & Prototypes

Our team of experts don’t just manufacture your metal laser cutting, we can also help with the prototyping and design

We have the experience to push our machines to the limits of their capabilities in order to meet engineering requirements. We work with our machine shop to build bespoke motor assemblies.

Pack & Wrap

We take the greatest of care with what we produce and how it is packed.

We provide logical batching of components.

Helpfully labelled boxes, crates or pallets make it simple.

Inspection At Every Stage

Every order at Coleherne adheres to a four-stage quality process:

Order and CAD checking.

CNC programming.

First off cut.

Final batch inspection.

Our Quality Assurance is augmented by:

ISO-9001:2015.

Digital shadowgraph and inspection gauges.

Manual and metrological inspection.

Verified materials with 3.1 certs when requested.